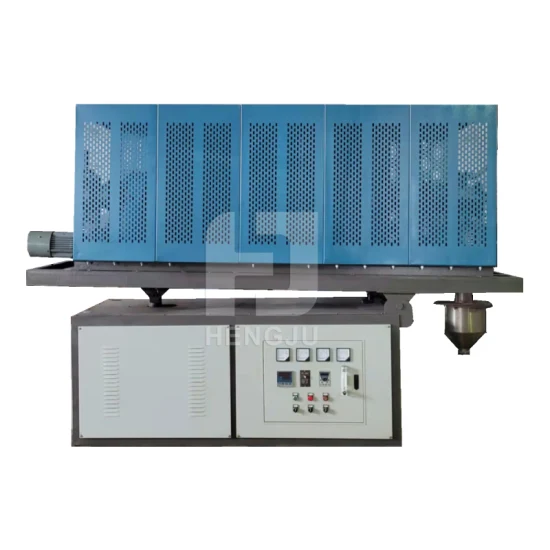

Capacitance Carbonization Battery Rotary Furnace Capacitance Refining Metal

Basic Info.

| Model NO. | HJ-450 |

| Certification | ISO, CE |

| Automation | Automatic |

| Screw | Multi-Screw |

| Treatment | Biological Treatment |

| Heater | Electric Wire or Silicon Carbide Rod |

| Rotating Speed of Furnace Tube | Variable Frequency Adjustable |

| Furnace Tube Material | High Temperature Alloy Stainless Steel |

| Maximum Operating Temperature | 1100 ºC |

| Production Mode | Continuous |

| Transport Package | According to Customer Requirements |

| Specification | Can be customized |

| Trademark | HENGJU |

| Origin | China |

| HS Code | 8417809090 |

| Production Capacity | 20 Items Per Month |

Packaging & Delivery

Package Size 600.00cm * 700.00cm * 800.00cm Package Gross Weight 4000.000kgProduct Description

Pyrolysis is a method of burning, smelting, sintering and melting electronic wastes to remove plastics and other organic components and extract metals.Electronic waste contains many precious resources. Recycling and recycling of electronic waste is an important way to solve resource shortage and environmental pollution. By improving the utilization rate of resources, turn waste into treasure, and give full play to the role of internal energy, including electronic waste.Main functions and characteristics of high-temperature pyrolysis rotary furnace:

1. Production mode: continuous

2. Maximum operating temperature: 1100 ºC

3. Furnace tube material: high temperature alloy stainless steel

4. Heater: electric wire or silicon carbide rod

5. Furnace material: alumina fiber+aluminum silicate fiber, with good temperature resistance, energy saving and thermal insulation performance.

6. Temperature control mode: intelligent PID control, self setting function, phase shifting trigger, over temperature alarm, leakage protection and other operating functions.

7. Temperature control accuracy: ± 1 ºC

8. Temperature control curve: 30 temperature rise and fall programs can be preset to meet the requirements of different working conditions.

9. Rotating speed of furnace tube: variable frequency adjustable

10. Inclination of furnace body: 0~30 degrees, adjustable

Q: Are the machines you produce all of a uniform standard?

A: We will customize the machine for you according to your requirements.

Q: How to choose the right machine?

A: Please tell us your raw materials for production and the output you need as well as other requirements, we will recommend the most suitable products for you.

Q: How is the machine installed?

A: Under normal circumstances, we provide the whole machine for delivery. We will provide detailed installation drawings for each machine. We can also arrange technicians to go to the site to guide the installation.

Q: What about the supply of main parts?

A: Spare parts will always be available at cost and a spare parts list will be provided when you purchase the machine.

Q: Do you test the machine before shipping?

A: Yes, we will test each machine and production line before shipment, and send you working video. You can also inspect your purchased machine at our factory before delivery.