Oxide Magnesium Oxide Magnesite MGO Caustic Calcined Magnesite CCM Refractory Material

Basic Info.

| Model NO. | 85/88/90/92 |

| Transport Package | PP Bags |

| Specification | 200mesh, 0-1mm, 1-3mm, 3-5mm |

| Origin | China |

| HS Code | 2519902000 |

| Production Capacity | 10000 |

Product Description

| MGO | FE2O3 | AL2O3 | SIO2 | CAO | IGL | |

| CCM90 | 90%MIN | 0.55%MAX | 0.42%MAX | 3.65%MAX | 1.9%MAX | 2.31-2.61 |

| CCM85 | 85%MIN | 0.54%MAX | 0.50%MAX | 4.88%MAX | 3.35%MAX | 4.1-4.3 |

Light-burned magnesia is to calcinate magnesite, brucite and magnesium hydroxide extracted from seawater or brine at about 800~1000ºC, decompose and discharge CO2 or H2O. Light burned magnesium is widely used in building materials, chemical industry, metallurgy, medicine and other fields. It is an ideal material for the production of fireproof boards, lightweight partition boards, magnesium sulfate, papermaking, desulfurization technology and slag splashing in steel mills. Light burned magnesia is calcined magnesite, brucite and magnesium hydroxide extracted from seawater or brine at about 800~1000°C, decomposed and discharged CO2 or H2O, that is, light burned magnesia powder, also known as light burned magnesia and caustic magnesium Burning or light magnesium burning, commonly known as bitter soil powder. Lightly burned magnesia powder is loose in texture and high in chemical activity, and can be used to make magnesium cement, magnesite building materials, heat insulation materials, etc. It is also an intermediate product for the production of high-quality magnesium oxide by two-step calcination. When light-burned magnesia is heated, equiaxed periclase appears at about 600 °C. When the temperature reaches 650°C, equiaxed periclase disappears and non-equiaxed periclase is produced. At 80°C, equiaxed periclase completely disappears. These periclase lattices have high surface energy due to point defects and dislocations. The crystal lattice of MgO has less water than the lattice group of MgCO3, so the pores between the lattices increase, the porosity is high, the specific surface area is large, and the activity is high. Lightly burned magnesium powder is light yellow and light brown powder, mostly below 100 mesh, and the periclase crystals are very small The light burning temperature and light burning time of light burnt magnesite have a certain influence on the activity of light burnt magnesite powder. Magnesite is calcined at 600°C, 650°C, 700°C, 750°C, 800°C, 850°C and 900°C, respectively, and the calcination temperatures of 700°C, 750°C and 800°C are within 15 to 90 minutes. Activity was not significantly affected. The effects of 600°C, 650°C, 850°C and 900°C on the activity are particularly significant, and the activity increases significantly with time when calcined at 600°C and 650°C. When calcined at 80°C and 900°C, the activity decreased significantly with the prolongation of hydrocarbon calcination time.

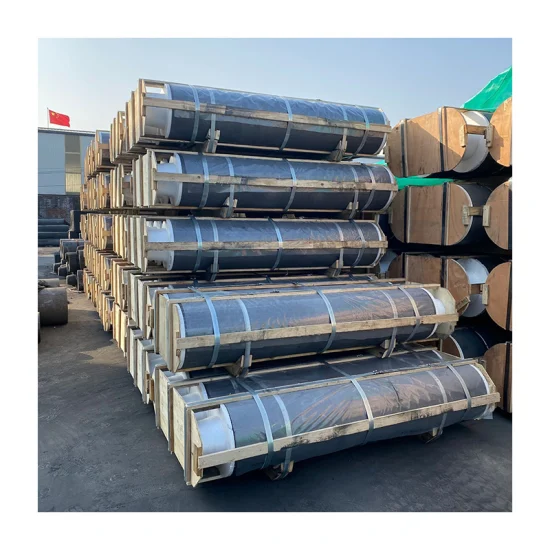

Our company has developed from a single dead-burned magnesia kiln workshop-style enterprise and has formed a complete system of production scale. It has a magnesium product processing plant, two dead-burned magnesia kilns, 14 light-fired kilns, a magnesium ball factory, a magnesium The second ball factory covers a total area of 45,000 square meters. The total production capacity has exceeded 100,000 tons. The products are electric furnace, converter, ladle refractory mixture, light burnt magnesia, heavy burnt magnesia, fused magnesia, mid-grade magnesia, high-purity magnesia, light burnt magnesia balls, modified Quality agent is the main product. A privately owned enterprise, the company has advanced equipment, high output, reliable quality and strong technical force. The company is a large magnesium production enterprise. After 14 years of extraordinary years, with the close cooperation and friendly help of friends from all walks of life, self-improvement and innovation have become the spirit of struggle. It is a professional manufacturer of non-metallic minerals for refractory materials. It has rich mineral resources, strong technical force, advanced Advanced production equipment and perfect quality management system.

In order to achieve better and faster development of the magnesite industry, our company has carried out long-term technical cooperation with Liaoning Magnesium Products Research Institute and Liaoning University of Science and Technology, forming a research, production and learning system, increasing Product quality and application effect.

Customer first, quality for survival, integrity for development" is our basic philosophy. We will provide you with better quality products as a sincere return to you.

DETAILS:

Can I get free samples?

A1.Yes, free samples 1-2 kg. Please advise your contact details. ( Like your company name, address, phone No. etc.) We will arrange sample immediately, you will get it within 5 days.

Q2. What's your payment terms?

A2.We can accept LC,DP,TT.

Q3. What's your delivery time?

A3.Production time: 15-25 days after deposit payment received.

Q4. Are you manufacturer or trade company?

A4.We are manufacture, the factory is located in dashiqiao, Liaoning Province, China. Welcome to visit our factory any time.