Small Aluminum Induction Electric Arc Melting Furnace Price for Sale

Basic Info.

| Output DC Voltage | 900V |

| Capacity | 1.5ton |

| Applicable Industries | Manufacturing Plant, Energy & Mining, Casting |

| Warranty of Core Components | 1 Years |

| Dimension(L*W*H) | 410*200*420mm |

| Usage Name | Melting Furnace |

| After Warranty Service | Video Technical Support, Online Support, Spare PAR |

| Type Name | Induction Furnace |

| Melting Material | Aluminiam Alloy |

| Size | Fit for 20gp,40gp,40hc Container |

| Transfport | by Sea Shipment |

| Color | Grey |

| Weight (T) | 1.7 T |

| Transport Package | Plywood or Non |

| Specification | 0.1T-10T Induction furnace |

| Trademark | HIKING |

| Origin | Weifang, China |

| HS Code | 85143000 |

| Production Capacity | 1000 Sets/Year |

Product Description

Product Description

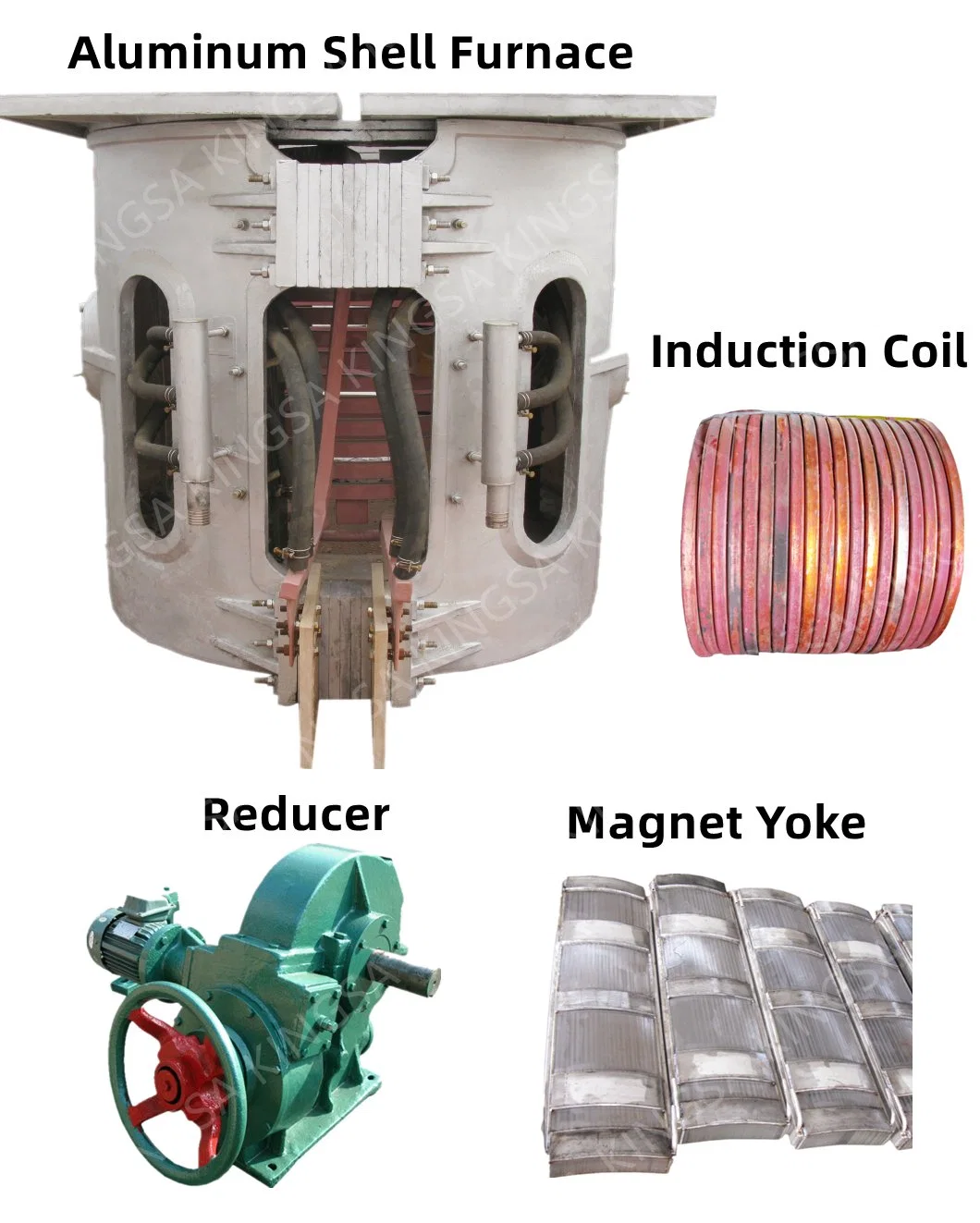

1. Product Name: Induction Furnace, Reducer Tilting Furnace,Coreless Medium Frequency Induction Furnace, Electric furnace for melting2. Model: GW0.1-10T3. Usage: Melting, heat holding, iron melting, steel melting, stainless steel melting, copper melting, brass melting, gold melting, aluminum melting.4. Equipment Composition(1 power work with 1 furnace pot and 1 backup pot):

| Item | Product Name | Qty | Unit | |

| 1 | Power Supply | Power Supply Cabinet | 1 | set |

| 2 | Capacitor | 1 | set | |

| 3 | Furnace | Medium Frequency Induction Furnace Pot(1 furnace pot for melting, 1 for backup) | 2 | set |

| 4 | Crucible Module | 2 | set | |

| 5 | Reduction Gear | 2 | set | |

| 6 | Furnace Support Shelf | 2 | set | |

| 7 | Water-cooled Cable | 4 | Pc | |

| 8 | Tilting Control | 1 | set | |

Induction Melting Furnace Features fast speed of melting, energy saving, less burnt loss, pure molten liquid.

- Customerized design acceptable

- No pollution

- High heating speed

- Low power consumption

- High temperature accuracy

Melting furnace's aluminum frame is adopted to small capacity melting furnace with reasonable structure and small capacity, convenient installation and simple maintenance, low maintenance cost

Equipment Parts Power Supply CabinetThe utility model has the advantages of obvious energy saving effect and 20% saving compared with common equipment.

It can achieve that one power supply cabinet for two furnaces.Transformer utilization rate is high.

The two furnaces can cast simultaneously and also can supply continuously molten steel casting.

Arbitrary power allocation, starting rate of 100%

Capacitor Bank

The double-layer mica insulation technology is used for the insulation treatment of the capacitor.Even if water is sprayed on the capacitor accidentally, the insulation strength of the cabinet can be ensured.

Medium Frequency Induction FurnaceIt has the bottom of the oxygen blowing, reducing carbon, slagging function.

Cyclone type smoke hood has excellent dust absorption , thermal insulation effect and take up a small space.

Long service life.

Tilting Reducer:The tilting reducer is equipped with three-stage turbine speed. With good self-locking and stable rotary performance.Induction Coil

Traditional winding,bakelite post fixed.The coil assembled from a solid, durable and highly conductive T2 copper tube.The water-cooled coil and the effective coil are integrally formed by a copper tube without segmentation. The two adjacent copper tubes of the induction coil are strictly insulated and adopt advanced segmentation technology. An insulating sheet is implanted between adjacent induction coils. After the insulating varnish is sprayed, it becomes a complete structure, and is pressed by the upper and lower steel structures in the furnace body, and the overall structure is firm and has no deformation problem. The coil turns are appropriate to achieve maximum electrical efficiency. The coil is supplied with cooling water from a plurality of water paths and evenly distributed. The outside of the coil is tightly wound with an insulating material. The inter-turn arc-shaped insulating spacers ensure uniform coil spacing and facilitate moisture removal.

Technological Process

The medium frequency smelting furnace mainly used for melting and refining all kinds of scrap metal, iron, stainless steel, copper, aluminum. This furnace can smelting the scrap iron, like scrap auto parts, scrap steel bars, scrap screws, iron leftover materials etc.

Product Features

1. Various capacity 0.1T -20T, fast melting speed, 40-60 minutes /pot2. Have self-test function, real-time supervise.3. Have leaking alarm device, PLC control, easy to operate.4.The control cabinet is standard of the automobile line, easy to maintain5. The water way uses carbon-free hose , water separetors and clips use 304 stainless steel6.Can meet 24 hours continuous work.7. High efficiency , low cost , easy to maintain, energy saving ,safe and stability.

| Furnace Model | Rated Capacity | RatedPower | MFFrequency | Power InputVoltage | MF OutputVoltage | Pulse | MeltingTime | ElectricityConsumption | TransformerCapacity Required | Water CoolingConsumption |

| T | KW | KHZ | V | V | Minutes/batch | KWH/T | KVA | T/H | ||

| GW-0.05T-100KW/1S | 0.05 | 100 | 1 | 380 | 750 | 6 | 30 | 800 | 120 | 5 |

| GW-0.1T-175KW/1S | 0.1 | 175 | 1 | 380 | 750 | 6 | 40 | 790 | 200 | 8 |

| GW-0.15T-160KW/1S | 0.15 | 160 | 1 | 380 | 750 | 6 | 50 | 780 | 250 | 8 |

| GW-0.25T-250KW/1S | 0.25 | 250 | 1 | 380 | 750 | 6 | 60 | 780 | 315 | 10 |

| GW-0.35T-300KW/1S | 0.35 | 300 | 1 | 380 | 750 | 6 | 60 | 770 | 400 | 12 |

| GW-0.5T-400KW/1S | 0.5 | 400 | 1 | 380 | 750 | 6 | 65 | 750 | 500 | 15 |

| GW-0.75T-500KW/1S | 0.75 | 500 | 1 | 380 | 750 | 6 | 65 | 750 | 600 | 20 |

| GW-1T-700KW/1S | 1 | 700 | 1 | 660 | 1200 | 6 | 70 | 720 | 900 | 25 |

| GW-1.5T-800KW/1S | 1.5 | 800 | 1 | 660 | 1200 | 6 | 70 | 690 | 1000 | 35 |

| GW-2T-1200KW/0.5S | 2 | 1200 | 0.5 | 660 | 1200 | 6 | 70 | 680 | 1250 | 40 |

| GW-3T-1800KW/0.5S | 3 | 1800 | 0.5 | 660 | 1200 | 6 | 65 | 620/560 | 1800 | 50 |

| GW-5T-3000KW/0.5S | 5 | 3000 | 0.5 | 660 | 1200 | 6 | 60 | 600/550 | 3600 | 55 |

| GW-10T-5000KW/0.5S | 10 | 5000 | 0.5 | 660 | 1200 | 6 | 70 | 550-600 | 6500 | 80 |

Why choose us? Aftersales Service:

Paper documents:We offer all related schemes for building furnace foundation, furnace installation, cables connections, pipes connections.Installation and commissioning: We offer engineers for assistant of equipment installation and commissioning.Spare parts support: We support all spare parts in time when there is need for all the time after sales.

Packing & Shipping

Small indution melting furnace will be packed by standard plywood case for exporting ;Suppose your order is of big valumn or 1pc furnace with large capacity, the products will be delivered by 20GP or 40GP container. Top open container is optional as well.