Lead Refining Furnace for Melting Lead Batteries

Basic Info.

| Model NO. | LF-20230718003 |

| Type | Steel-Making Equipment |

| Certification | ISO, CE |

| Produce Time | 3 Month |

| Industrial Voltage | 380V.3p.50Hz or Customized |

| Materials | Q235r |

| Transport Package | Whole Container |

| Specification | 56cbm |

| Trademark | lufeng |

| Origin | China |

| Production Capacity | 50unit Per Year |

Product Description

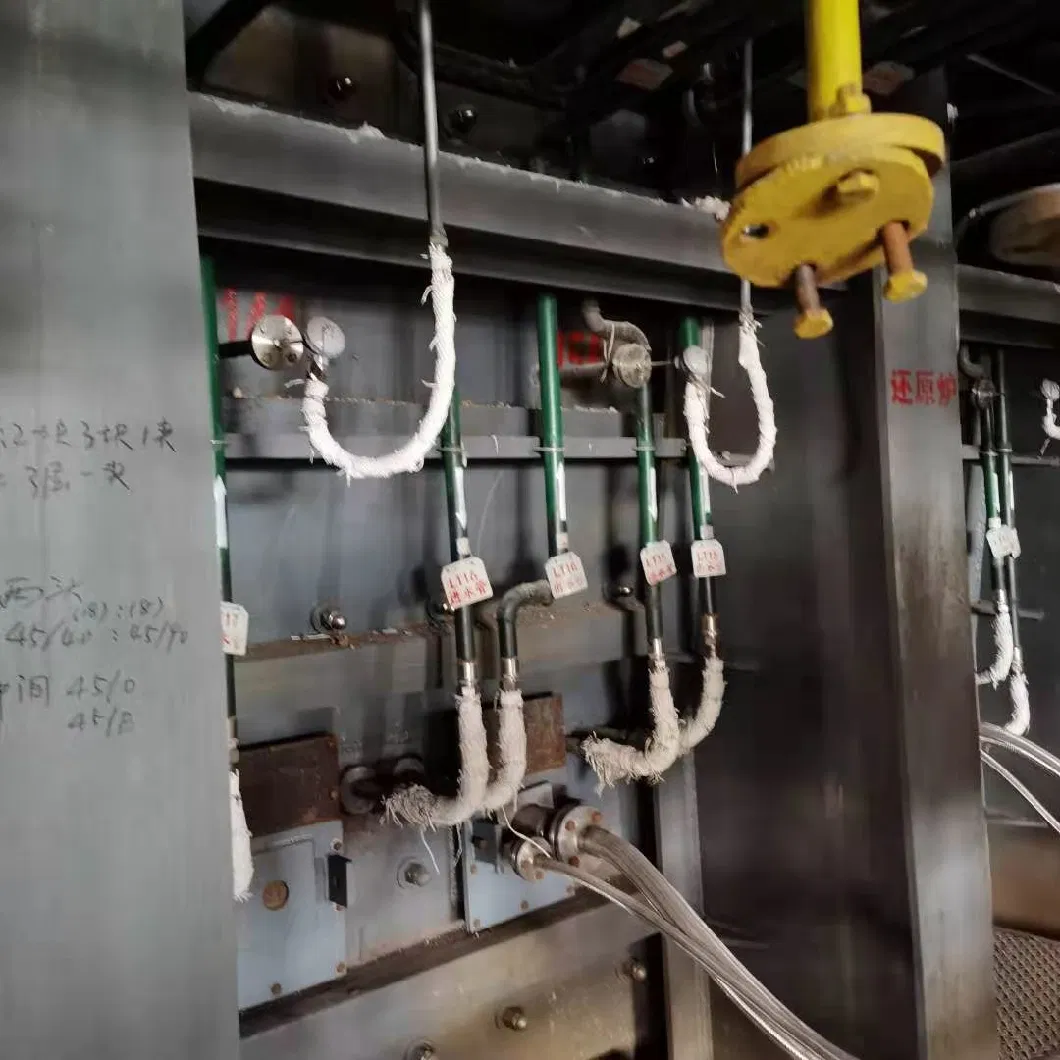

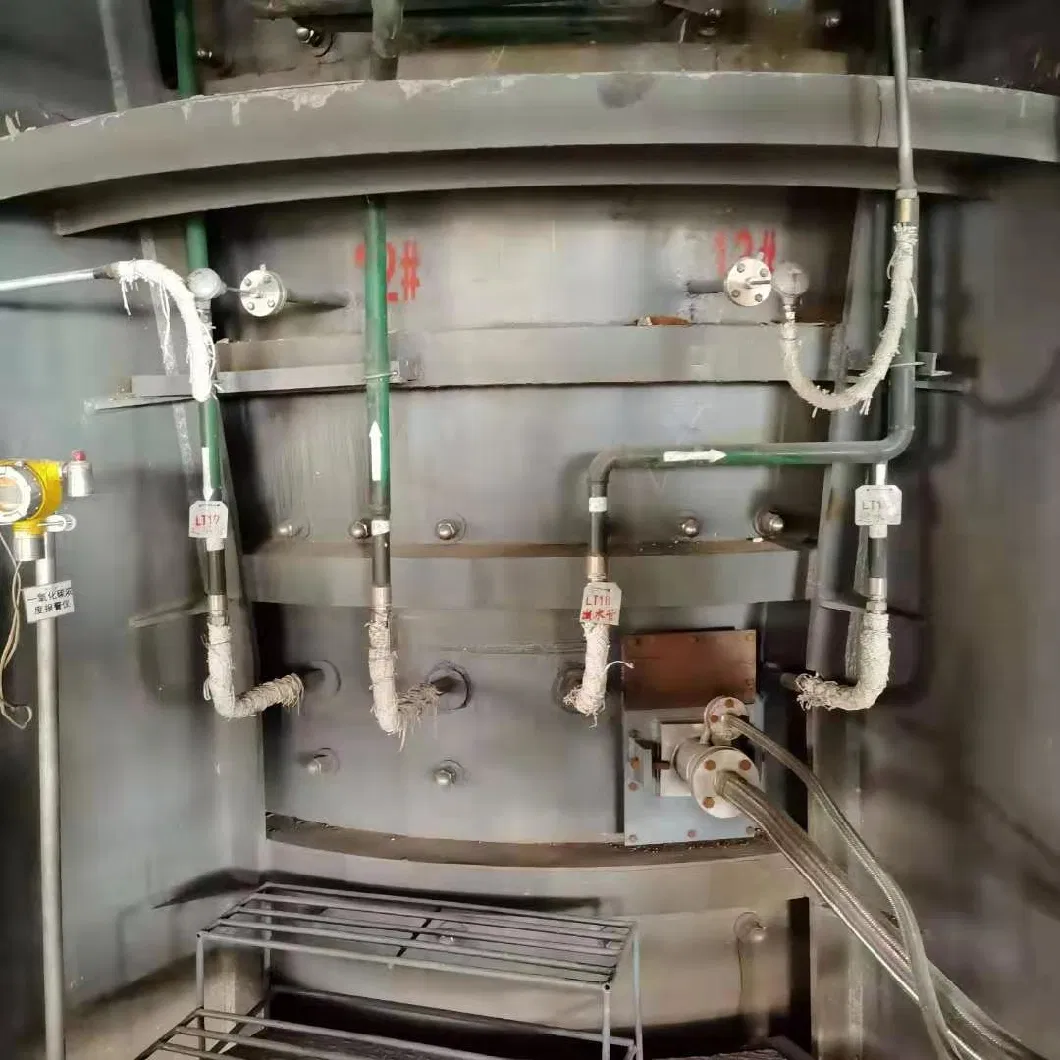

Reflection refining furnace

The present invention discloses a bottom blowing process for alkaline refining of regenerated lead by fire method. After the crude lead liquid is poured into the refining furnace from the melting furnace, argon gas is introduced from the bottom. When the temperature of the lead liquid drops to about 330 ºC, slag is skimmed, and the lead copper content is reduced to about 0.1% by melting and removing copper. After skimming, sulfur powder is sprayed into the bottom of the refining furnace to further remove copper. The temperature is raised to 450-480 ºC, and the reaction is carried out for 30-60 minutes. The sulfide slag is removed to complete the copper removal process; When the lead liquid temperature is about 450 ºC, powdered Sodium nitrate and sodium hydroxide are blown from the bottom of the refining furnace. After reaction for 30min, NaCl powder is blown from the bottom of the refining furnace with argon gas to complete the arsenic, antimony and tin removal process. The loss of said bottom blowing process method, refining agent and/or alloy is greatly reduced; There is only inert gas with low solid solubility in the lead liquid, which is not easily oxidized by the lead liquid and lead ingot. There is no lead slag inside the lead liquid and lead ingot. When using recycled lead, there is less lead slag and the slag yield is low; During the refining process, the surface of the lead liquid is always protected by argon gas, which can be used for high-temperature Ag removal operations. The regenerated lead contains low Ag content; The argon gas blown into the bottom will float together with small bismuth compound particles, resulting in low bismuth content in lead ingots