Provide Solution Arc Melting Furnace Submerged Arc Furnace Electric Arc Furnace Price for Ferrosilicon Silicomanganese Ferrochromium

Basic Info.

| Condition | New |

| Power Source | Electric |

| Automatic Grade | Automatic |

| Type | Steel-Making Equipment |

| Certification | CE |

| Incoming Line Voltage | 10kv |

| Melting Time | 2 Hours |

| Discharge Method | Hydraulic Dumping |

| Transformer Capacity | 5000kVA |

| Power | 4000kVA |

| Furnace Shell | 5500*3400(Dia*H) |

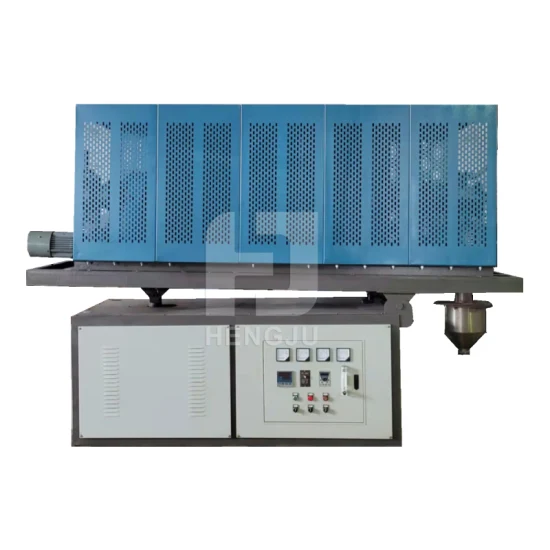

| Product Name | 4000kVA 10tons Electric Arc Furnace |

| Application | Steel Scrap Melting |

| Transport Package | Wooden Package |

| Trademark | Dming |

| Origin | China |

| HS Code | 8514300090 |

| Production Capacity | 200 Sets Per Month |

Product Description

Product DescriptionProvide Solution Arc Melting Furnace Submerged Arc Furnace Electric Arc Furnace Price for Ferrosilicon Silicomanganese Ferrochromium

Not only electric arc furnaces, but also production process guidance

Application

Steelmaking electric arc furnaces are used in steelmaking short-flow smelting processes, using 100% steel scrap or scrap steel + molten iron (pig iron), or scrap steel + sponge iron (DRI) as raw materials for steelmaking. According to the power equipped with the furnace, it is divided into ordinary power, high power, and ultra-high power electric arc furnace. Modern steelmaking electric arc furnaces widely adopt new technologies such as water-cooled furnace cover, water-cooled furnace wall, conductive cross arm, and eccentric bottom (EBT) tapping; adopt comprehensive energy utilization technology, equipped with furnace door carbon oxygen lance and furnace wall cluster oxygen lance, The secondary combustion of the CO escaping from the molten pool is effective in making full use of the chemical energy in the flue gas to reduce power consumption and create foam slag; adopt high-impedance technology to increase the secondary voltage to achieve long-arc smelting, and the arc is relatively stable. The impact on the power grid is reduced, the short-circuit system current is smaller, the energy consumption and electrode consumption are reduced, and the effective input of electric power is improved.

Various forms have their own characteristics. Our company can select and design according to user needs. The structure can be complex or simple, and the configuration can be high or low.

The complete set of steel-making electric arc furnace equipment includes: furnace body, tilting platform, molten steel transport vehicle, water-cooled furnace cover and smoke and dust collection device, furnace cover rotating lifting mechanism, copper-steel composite conductive cross arm and electrode lifting device, secondary short net , Hydraulic system, water cooling system, argon blowing system, ladle furnace transformer, high voltage system, low voltage electric control and PLC automatic control system.

Steelmaking electric arc furnace is used in the short-flow smelting process of steelmaking, using 100% steel scrap or scrap + molten iron (pig iron), or scrap + sponge iron (DRI) as the charge for steelmaking. According to the furnace cover rotating mechanism, it can be divided into independent foundation, basic conjoined, large slewing bearing and four-link structure. Modern steelmaking electric arc furnaces have widely adopted new technologies such as water-cooled furnace covers, water-cooled furnace walls, conductive cross arms, and eccentric bottom tapping (EBT).

Features1.Can flexibly control the smelting temperature to meet different smelting needs2.High thermal efficiency, the atmosphere in the furnace can be controlled3.A large amount of phosphorus, sulfur, oxygen and other impurities in steel can be removed, and the quality of steel can be improved4.The chemical composition of steel is relatively easy to control, and the recycling rate of the alloy is high and stable5.Simple equipment and short process flow

| Model | Inner Diameter | Transformer Capacity | Electrode Diameter | Cooling Water Consumption | Weight |

| DM-HX-0.5 | 2100mm | 650KVA | 150mm | 30T | 5T |

| DM-HX-1.5 | 2500mm | 1250KVA | 200mm | 45T | 9T |

| DM-HX-3 | 3000mm | 2200KVA | 250mm | 50T | 24T |

| DM-HX-5 | 3400mm | 3200KVA | 300mm | 80T | 34T |

| DM-HX-10 | 3500mm | 6300KVA | 350mm | 130T | 74T |

| DM-HX-15 | 3800mm | 8000KVA | 350mm | 180T | 85T |

| DM-HX-20 | 4200mm | 10000KVA | 400mm | 240T | 98T |

| Can Be Customized | |||||

Dming Technology is the leading manufacturer of lab furnace, industrial furnace and the related accessories.As a manufacturer with more than 10 years' experience in thermal engineering, Dming Technology offers the wide and deep range of furnaces worldwide. Satisfied customers in more than 30 countries offer proof of our commitment to excellent design, quality and cost efficiency.Dming Technology offers a complete line of high temperature processing technologies in many styles and configurations.From muffle furnaces, Melting furnace, distillation furnace, electric arc furnace to vacuum sintering furnaces(Powder Metallurgy), Mesh belt furnace,oil gas quenching furnace and large-scale production ceramic kilns.Our customized solutions include products and heat treatment processes designed to meet specific customer requirements, and provide sample testing until the customer is satisfied.

Q1. How is your company's product after-sales service system?

A. We have professional pre-sales and after-sales departments and

can respond to you within 8 hours to resolve any technical issues.

Q2. How about the quality guarantee period?

A:2 years, exclude irrationally operating and consumable parts.

Q3. How about your products quality?

CE certification available and twice test before shipping.

Q4. What's your delivery time?

90 days

Q5. Are you a manufacturer or a trading company?

We are a factory with 10 years experience in the field.

Not only electric arc furnaces, but also production process guidance